Knowing that the best LED lights begin from high-quality materials, we regularly audit our supplier base to maintain our production standards, including delivery consistency, material quality, and proper processing

Equipment used for making the materials are checked to make sure our suppliers have quality certifications.

Along with the equipment, production guidelines are reviewed for optimal, safe, and eco-friendly processing.

We also look for the best prices in the market, so we can provide you competitively-priced products.

Our pool of suppliers has a consistent record of meeting required delivery timeframes, never skipping a beat.

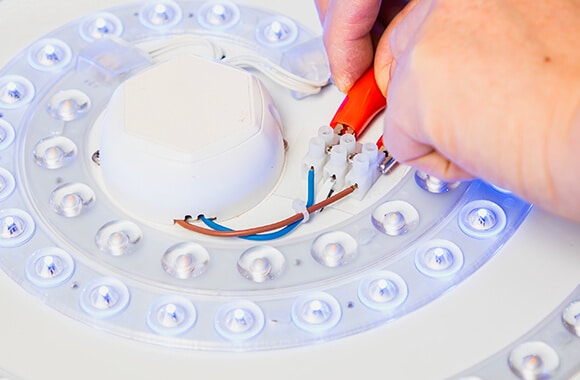

Building primary components of our LED lights in-house is an essential step in maintaining quality control throughout the production. Each part is verified by our IQC department, with parts not meeting our standards properly discarded. This reduces the risk of defective or poor-quality products down the line, minimizing returns.

LED lights are subjected to various quality testing after every step in the manufacturing process based on company and international quality standards. Defective or poor-quality products are taken out, and only those who pass 100% are packed and prepared for shipment. Our process is your guarantee for reliable LED lights.

LAC utilizes a standard series of processes and tests to guarantee our products have smart control functions and long-lasting while delivering quality lighting to users.

The exterior of our LED lights is routinely inspected for impurities or visual defects, which are taken out from the production line.

Trusted and qualified third party inspectors check our manufacturing process and equipment on a regular basis, allowing us to keep our high management standards like the BSCI certification.

Our certified process and production line make sure you get the best products from us.

On time delivery (OTD)

First Pass Yield

Customer satisfaction score (CSAT)